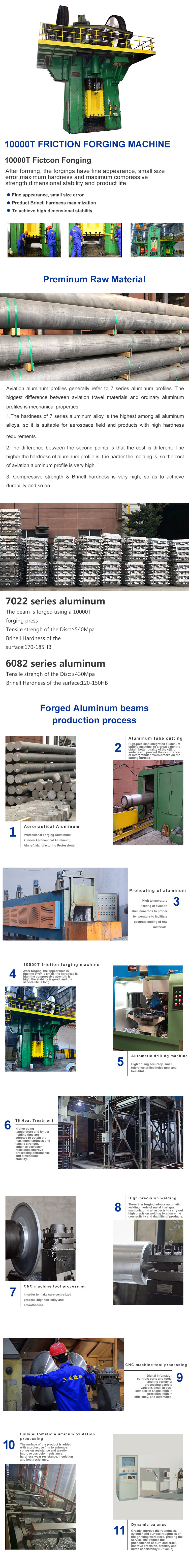

10000T FRICTION FORGING MACHINE

10000T Fictcon Fonging

After forming, the forgings have fine appearance, small size error,maximum hardness and maximum compressive strength,dimensional stability and product life.

- Fine appearance, small size error

- Product Brinell hardness maximization

- To achieve high dimensional stability

Preminum Raw Material

7022 series aluminum

The beam is forged using a 10000T forging press

Tensile strengh of the Disc:≥540Mpa

Brinell Hardness of the surface:170-185HB

6082 series aluminum

Tensile strengh of the Disc:≤430Mpa

Brinell Hardness of the surface:120-150HB

Aviation aluminum profiles generally refer to 7 series aluminum profiles. The biggest difference between aviation travel materials and ordinary aluminum profiles is mechanical properties.

1.The hardness of 7 series aluminum alloy is the highest among all aluminum alloys, so it is suitable for aerospace field and products with high hardness requirements.

2.The difference between the second points is that the cost is different. The higher the hardness of aluminum profile is, the harder the molding is, so the cost of aviation aluminum profile is very high.

3. Compressive strength & Brinell hardness is very high, so as to achieve durability and so on.

Forged Aluminum beams production process

1

Aeronautical Aluminum

Professional Forging Aluminum: 7Series Aeronautical Aluminum, Aircraft Manufacturing Professional Materials

2

Aluminum tube cutting

High-precision integrated aluminum cutting machine, to a great extent,to obtain better quality of the ctting surface and prevent the occurrence of intergranular micro-cracks on the cutting surface

3

Preheating of aluminum

High temperature heating of aviation aluminum rods to proper temperature to facilitate accurate cutting of row materials.

4

10000T friction forging machine

After forging, the appearance is fine,the error is small, the hardneas is high,the compressive atrength is high, the stability is good, and the service life is long.

5

Automatic drilling machine

High drilling accuracy, small tolerance,drilled holes neat and beautiful.

6

T6 Heat Treatment

Higher aging temperature and longer holding time are adopted to obtain the maximum hardness and tensile strength, enhance corrosion resistance,improve processing perfomance and dimensional stability.

7

CNC machine tool processing

In order to make sure centralized process ,high flexibility and smootheness.

8

High precision welding

Three Star forging adopts automatic welding mode of metal inert gas manipulator in all aspects to carry out high precision welding to ensure the connectivity and ductility of products.

9

CNC machine tool processing

Digital infomation controls parts and tools, and the variety of processing parts is variable, small in size, complex in shape, high in precision, high in efficiency, and automated.

10

Fully automatic aluminum oxidation processing

The surface of the product is added with a protective film to enhonce corrosion resistance and greatly improve corrosion resistance, hardness,wear resistance, insulation and heat resistance。

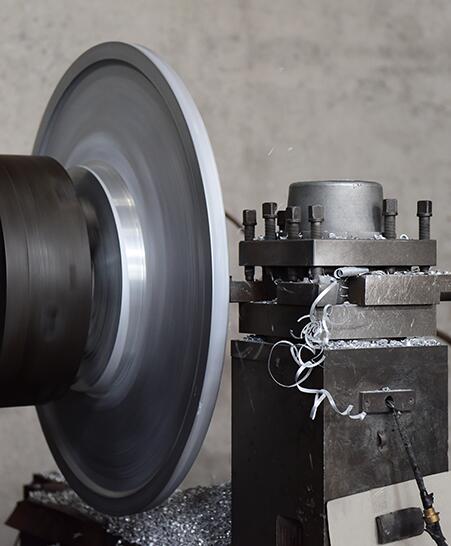

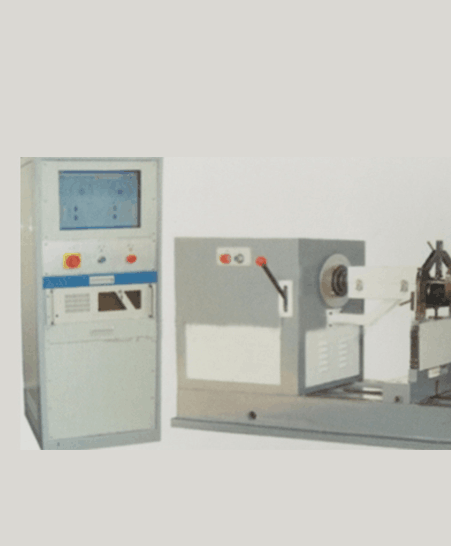

11

Dynamic balance

Greatly improve the roundness, cylinder and surface roughness of the grinding workpiece, prolong the service life, reduce the phenomenon of burn and crack, improve precision, stability and batch consistency (CP value)